Siemens Digital Industries Software announced the duo at DAC 2025. The Innovator3D IC suite advances 3D IC integration using AI to execute chip design and raise productivity, as designers increasingly reintegrate chiplets into high performance substrates, said the company.

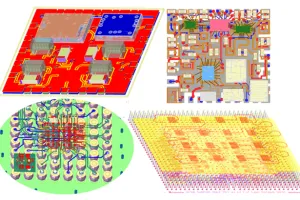

It enables IC designers to efficiently author, simulate and manage heterogeneously integrated 2.5D/3D IC designs with a fast, predictable path for planning and heterogeneous integration, substrate/interposer implementation, interface protocol analysis compliance and data management of designs and design data IP.

Trained on user-experience AI, it has multi-threading and multi-core capabilities to optimise capacity and performance on designs in excess of 5m pins. Its Innovator3D IC Integrator is a consolidated cockpit for constructing a digital twin using a unified data model for design planning, prototyping and predictive analysis. It also includes Innovator3D IC Layout for correct-by-construction package interposer and substrate implementation. Other elements are the Innovator3D IC Protocol Analyzer for chiplet-to-chiplet and die-to-die interface compliance analysis and Innovator3D IC Data Management to manage designs and design data IP.

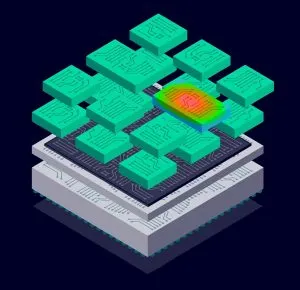

The second announcement is the Calibre 3DStress software, designed to identify the electrical impact of stress at the transistor level. It uses advanced thermo-mechanical analysis to optimise the yield, reliability and complexity (pictured).

The challenge is that 2.5D/3D devices have thinner dies and higher package processing temperatures. For this reason, the software supports transistor-level analysis, verification, and debugging of thermo-mechanical stresses and warpage in 3D IC packaging. Chip designers are therefore able to evaluate chip-package interaction earlier in the development cycle.