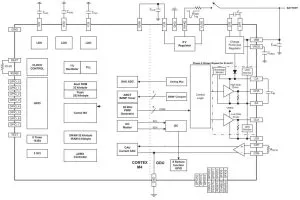

The power modules will be in Infineon’s HybridPack Drive G2 format (pictured) and include both silicon and silicon carbide components. Along with these, Rivian has picked infineon’s established TC3x MCUs, not not its new TC4x family – both of which have its proprietary TriCore CPUs rather than x86, Arm or RISC-V.

At the moment, Infineon only has four G2 HybridPACK Drive modules, all three-phase bridges: 750V/620A or 1.2kV/390A with SiC mosfets, or a pair of 750V/1150A Si IGBT modules.

Rivian has picked two of the G2 modules, both 750V, one SiC mosfet and one Si IGBT. They will have the short hole-less ac and dc power tabs (pictured) as Rivian will be welding the high-current connections rather than bolting.

The packages are direct-liquid-cooled, having pin-fin arrays as their thermal interface and main insulator is silicon nitride. Thermal resistance is typically 0.129°C/W to a 65°C 1litre/min 50/50 water/ethylene glycol mix. Three silicon diodes are provided for temperature monitoring.

Electrical interfaces are press-fit pins on the low-power side and metal tabs for high power.

Compared with the company’s similar earlier (non-G2) packages, it claims higher temperature cycling capability and altered plastic for better temperature performance.

Infineon is expanding 200mm SiC production at its Kulim fab, and also has SiC production at its Villach fab.

Rivian vehicles are built in the US and sold directly to consumer and commercial customers.