Called STC31, it is aimed at ‘controlled atmosphere’ transportation, where CO2, humidity and temperature are monitored and set to preserve the freshness of fruits and vegetables.

“Exact conditions depend a lot on the exact commodity, with typically a low temperature, high humidity and CO2 concentration somewhere between 1% and 20%,” according to the company.

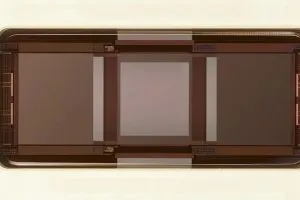

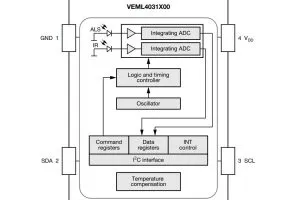

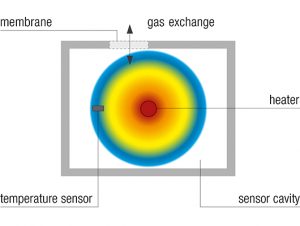

Called STC31, the sensor works by measuring the thermal conductivity of the gas in its environment (diagram left) and delivers both CO2 concentration and temperature over its I2C interface.

Called STC31, the sensor works by measuring the thermal conductivity of the gas in its environment (diagram left) and delivers both CO2 concentration and temperature over its I2C interface.

Built in is an option to compensate for the humidity – relative humidity has to be communicated to the STC31, and with this information the sensor will output a compensated concentration value. When no humidity value is delivered, it assumes a relative humidity of 0%.

Power consumption averages to 15µW at one measurement per minute, suiting it to battery power.

“By relying on the thermal conductivity technology, the sensor offers low power consumption, even compared to low-power optical sensors,” said the company.

Accuracy is 0.5vol% and ±3% of measured value, and the response time is <1s.

Construction is CMOS and the chip includes sensor, signal processing and digital calibration.

The package is 3 x 3.5 x 1mm.

| Calibrated for | CO2 in N2 CO2 in air |

| Measurement range | 0 to 100 vol% |

| Accuracy | < 0.5 vol% (+3% of mv) |

| Repeatability | 0.2 vol% |

| Resolution | 16bit |

| Measurement range | -20 to 85°C |

| Resolution | 16 bit |

| Temperature accuracy |

0.5°C (10°C to 50°C) 1.5°C (-20°C to 85°C) |

| Repeatability | 0.1°C |

| Supply | 2.7 – 5.5V |

| Max load | 5mA |

| Power (1measurement/min) | 15µW |

Electronics Weekly

Electronics Weekly