“Previous full metal proximity sensors have struggled to differentiate efficiently between these metals because the sensing distance for aluminium is shorter than that for iron. This makes the design, start-up, and maintenance of production lines complicated,” according to RS Components, which is stocking the pasts, called the E2EW series.

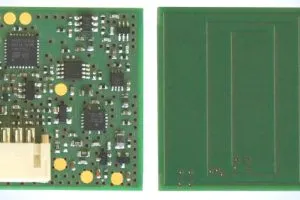

Models come in various diameter and various sensing distances – the quad-distance M18 (threaded 18mm diameter, pictured) model has a sensing range of 12mm for Al and Fe, where it was 2mm of Al and 7mm for Fe with earlier parts. M30 E2EW sensors can detect at 22mm. Sensing distance is printed on its head to prevent replacement errors.

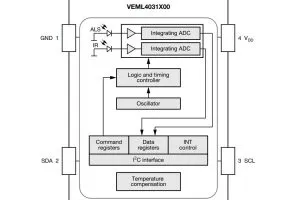

“The problem of previous full-metal body proximity sensors was the short sensing distance, said Omron. “E2EW sensors are equipped with Omron’s unique technology for suppressing noise influence as well as pulse response detection technology to detect current changes of sensing objects when pulsed currents are applied to coils technology. The technologies reduce the influence of noise, enabling the extended sensing distance. Furthermore, equivalent long distance detection for iron and aluminum is possible by adjusting the timing and time to detect current changes of sensing objects.”

To prevent metal spattered from the weld sticking to the sensor, models are available with a fluororesin coating that is said to last up to 60 times longer than with previous models, partly through improved attachment to the underlying metal body.

Data connection is through I/O Link.

RS is offering this link to the parts

There is plenty of good information in this document on the sensors

Electronics Weekly

Electronics Weekly