The IC is a custom transistor array sensitive to carriers released by the coating.

Designed to be spray-applied, the active parts of the coating are quantum dots, mostly made from perovskites.

While they are sized to detect x-rays, they can also be composed and sized for sensitivity to the spectrum between blue and short-wave infra-red (400 to 1,300nm), and also to both spectra.

“Direct-conversion design eliminates the need for scintillators, hybrid bonding or materials like InGaAs,” according to CSEM.

The technology was originally developed for embedding into aircraft structures to detect internal damage without disassembly, but now its designers are extending it for use in portable X-ray devices, mammography, crop health monitoring, and sorting plastics, fabrics or other organic materials.

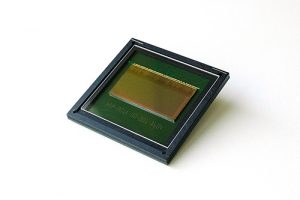

Finished sensor on an evaluation board

Finished sensor on an evaluation board

The sensor was developed under the Swissmodics project, led by CSEM and funded by the EU’s Clean Sky 2 program, with support from SERI (Swiss state secretariat for education, research and innovation) under its SwissChips initiative.

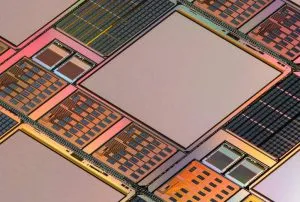

(Top photo: read-out IC and test structures on wafer prior to dicing)

Electronics Weekly

Electronics Weekly