Wireless technologies are increasingly relied on in multiple environments

As dependence on wireless devices that emit RF radiation continues to grow, so do the complexities of those devices and their international regulatory requirements. Specific absorption rate (SAR) testing plays a crucial role in assessing and ensuring the safety of such electronic devices, and their compliance to international standards and regulations.

SAR measures the rate at which the human body absorbs RF energy from a wireless device. Testing determines the amount of RF energy absorbed by the body, particularly in areas where the absorption is highest, such as the head and torso.

The results are expressed in Watts per kilogram (W/kg), representing the amount of RF energy absorbed per unit of body mass. Typically, the SAR levels are averaged over a 10g mass for European regulatory requirements and a 1g mass for North America.

The primary concern associated with RF radiation exposure is the potential for thermal effects, where the absorbed energy can lead to an increase in localised body temperature. SAR testing helps to establish whether a device emits RF energy at levels that may contribute to additional localised heating effects.

Regulatory compliance

SAR testing is a mandatory regulatory requirement in many countries to ensure that electronic devices comply with established safety standards. Different regions have specific SAR limits that devices must adhere to in order to be deemed safe for use.

Both the Federal Communications Commission and Innovation, Science and Economic Development in North America, and the European Union all have stringent SAR regulations.

The simplest way to decide if SAR testing is required is to ask: “Is the device to be used within 200mm of a user?” If the answer is “yes” and the output power of the device is generally, in the case of Europe, above 20mW, it is most likely that SAR testing would need to be carried out.

Mobile phones

SAR testing is mandatory for mobile phones and smartphones. Given the proximity of these devices to the user’s body, especially during calls, SAR testing ensures that the emitted RF energy is within safe limits.

As mobile phones are typically used against the head and the body, they must be considered for all their various user cases and the regulatory requirement for these conditions may be different. The devices may operate at different output power levels for those use cases. This needs to be considered both during the testing and in defining a test plan, as testing may need to be repeated for each use case.

Different national regulators operate in different global market regions. It is often the case that the maximum output power that can be accommodated varies within these markets. Where this is the case, entire test plans may have to be repeated. Most manufacturers will prefer to test with the maximum allowed output power being fully utilised as the signal quality will define the performance of any given device. Any reduction of output power may result in the device under test gaining a reputation for poor quality or sub-standard general performance. This means that testing once for only the most stringent of global limits is not necessarily the best strategy.

Body testing has become every bit as important as head testing, particularly following the introduction of ‘always-on’ data services. These technologies can be classed as an un-attended service, meaning that the device can be placed anywhere about the body with the user (in most cases) being unaware of the transmit status of the device. For example, the device could be doing an update, sending a large file, or being used by a third party as a Wi-Fi hotspot. Following the introduction of this technology the amount of regulatory testing that is required increased significantly and the allowable separation distance between the device and the body reduced significantly. These changes made the SAR testing of mobile handsets much more demanding.

Wireless consumer products

Devices such as tablets, smartwatches and other wireless communication devices that are used near the body are also subject to SAR testing. This includes devices with Wi-Fi, Bluetooth and cellular connectivity. As some of the devices in this category can be used in the hands or on limbs, a slightly relaxed SAR test limit might be allowed as these extremities do not contain any major organs and are primarily made up of skin, bone and muscles. Once again, it’s important to consider all the use cases. For example, a smartwatch could be classed as limb-only use, but if it is designed for the user to speak into it, then the proximity of the user’s face to the device when speaking into it must be considered. This front of face condition could result in a head SAR use case condition with a separation distance of 10mm, which would need to be tested to the more stringent head and body SAR limits, as well as testing the limb conditions.

Wireless infrastructure

In addition to individual devices, SAR testing is sometimes applicable to wireless infrastructure components, such as antennas and base stations, to ensure that the overall RF exposure levels are within acceptable limits.

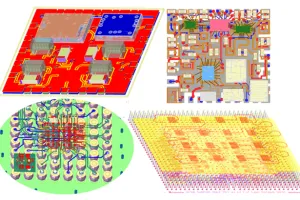

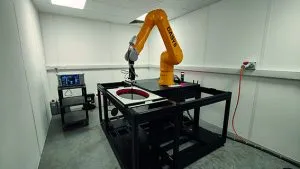

An SAR lab can test individual devices and wireless infrastructure components

As the use of small (pico-cell) office-based base station infrastructure technologies is becoming more widespread, how they are installed in the workplace must be considered. In the case of a base station, it’s often the device’s compliance distance that is important. If the minimum distance a user can get to a device and still meet the regulatory requirements is known, then the placement of that device in the workplace can be easily assessed.

For example, if the base station is compliant at 0mm separation distance then it can effectively be placed anywhere. Alternatively, if the separation distance is relatively large then this could be mitigated by specifying a minimum height at which the base station could be mounted on an office wall.

Certain medical devices that use wireless technology, such as wearable health monitors or implantable devices, may also require SAR testing to national regulatory requirements. It is therefore important to understand and define how a product will be used to understand when and how SAR tests will be applied.

Another key requirement is to understand and apply all ‘reasonably foreseeable use’ conditions. Examples of this would be for a mobile phone where a manufacturer has stated that it’s used in a body condition at a separation distance of 15mm, when, in reality, most users are placing the device in a pocket. In this case it is the pocket use case at a distance of up to 5mm that must be assessed. Similarly, if a device is classified as for use only in the hands when it can be placed in a pocket while it is transmitting, then body conditions would also need to be applied.

The other conditions that are important to consider is whether the device under test is for public use or for occupational use. If a device is for occupational use, the SAR limits are less stringent. The reason behind this is that professional users can be given training on the operation of equipment and on how to limit exposure to the RF radiation from those devices.

If a device is classed as occupational use, it may have been designed to the limits associated with occupational use and manufacturers must be certain that the device cannot be easily obtained by the general public. If this is not the case, then the device must be tested to the general public limits. Here, it is important to bear in mind that SAR testing is a physical test that must be carried out on hardware that is representative of that which is being placed on the market. Any issues that need to be fixed at the end of a product development cycle would be far more costly to rectify than if found earlier in the development cycle.

In most cases a fix for SAR compliance issues is to turn down the output power of a product, although this will negatively affect device performance. When a device is being developed, it is important to fully understand SAR testing requirements from the start. This will ensure that a practical and realistic SAR test programme is carried out as soon as possible in a product’s development cycle, to minimise the likelihood of costly design reworks, which can delay time-to-market.

Electronics Weekly

Electronics Weekly