Called OpenFlexure microscope, “it is unique among 3D-printed microscope in its ability to yield high-quality images,” according to the university.” It has been designed to be easy to use, with an intuitive software interface and simplified alignment procedures. It is also highly customisable, meaning it can be adapted for laboratory, school and home use.

For the first time, labs around the world can 3D print their own precision microscopes to analyse samples and detect diseases.”

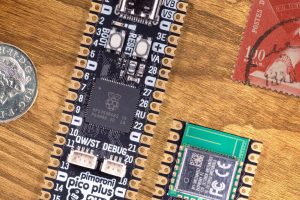

£15 would cover the cost of the printed plastic, a camera and some fastening hardware. A fully-automated, laboratory-grade instrument with motorised sample positioning and focus control, said Bath, would cost a couple of hundred pounds to produce, and would include a microscope objective and an embedded Raspberry Pi computer.

The design is up-side-down compared with traditional microscopes, with the light source at the top and viewing lens underneath, with camera at the base. Sample movement is through flexing structures with small stepper motors – positioning can be as good as 70nm steps horizontally, with vertical steps down to 50nm, and position is “stable to within a few microns over several days”, according to the team. The image sensor is an 8Mpixel Raspberry Pi V2 camera, which is built around a Sony IMX219. Its ~3,000 pixels are focused across ~150μm in one application example.

Software is available to control the microscope remotely over Ethernet or Wi-Fi.

“We want these microscopes to be used around the world – in schools, in research laboratories, in clinics and in people’s homes if they want a microscope just to play with. You need to be able to pick it up and use it straight away. You also need it to be affordable,” said Bath physics researcher, and microscope co-creator Dr Joel Collins.

Over 100 OpenFlexure microscopes have been printed in Tanzania and Kenya. “Our Tanzanian partners, STICLab, have modified the design to better suit their local market, demonstrating another key strength of open source hardware – the ability to customise, improve, and take ownership of a product,” said fellow creator Dr Richard Bowman.

Over 100 OpenFlexure microscopes have been printed in Tanzania and Kenya. “Our Tanzanian partners, STICLab, have modified the design to better suit their local market, demonstrating another key strength of open source hardware – the ability to customise, improve, and take ownership of a product,” said fellow creator Dr Richard Bowman.

Bowman, has been working on the OpenFlexure project since its inception, first from the University of Cambridge and then from the Department of Physics at Bath, has been looking at efforts to make open-source ventilators for Covid-19. “The medical device industry is very conservatively regulated, and it would be a good thing if all of this new attention [in 3D printed hardware] means there’s some re-thinking done about how we can uphold high safety standards but make it easier to build something if you’re not a mega corporation.”

OpenFlexure Microscope is described in detail in the paper ‘Robotic microscopy for everyone: the OpenFlexure microscope‘, published in Biomedical Optics Express – available free in full.

OpenFlextureIndustries is scheduled to sell kits

There is a video.

Project funding came from the Royal Commission for the Exhibition of 1851, the Engineering and Physical Sciences Research Council and the Royal Society.

Electronics Weekly

Electronics Weekly