This paves the way to producing high-resolution and large organic electroluminescent (EL) displays and establishing cost-competitive manufacturing methods.

Organic EL displays can be made thin and flexible with excellent response time and contrast ratio.

Products require organic EL displays of high pixel density, i.e. around 200ppi for 4K televisions, 500ppi for full HD mobile devices and even higher density for compact displays for wearable devices.

There has been active R&D for organic semiconductors to develop a high-resolution patterning method for organic EL materials to be used in these products.

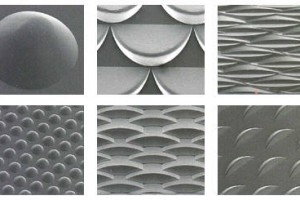

In 2013, Fujifilm and imec jointly developed photoresist technology for organic semiconductors that enables submicron patterning without damaging the organic semiconductor materials, based on photolithography capable of high-resolution patterning on large substrates.

There is no need for additional capital investment since an existing i-line exposure system can be used for the new technology. This is why the technology has attracted wide attention since the development announcement with anticipation of a cost-effective way of manufacturing high-resolution organic semiconductor devices.

In the latest achievement, Fujifilm and imec produced full-colour OLEDs with the photoresist technology for organic semiconductors and successfully verified their performance.

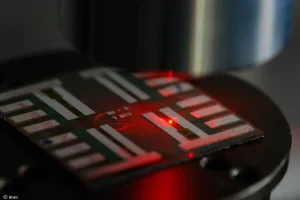

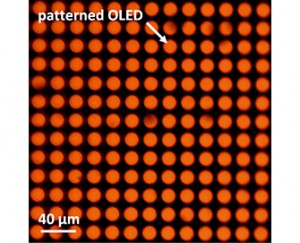

Red, green and blue organic EL materials were patterned, each in the subpixel pitch of 20μm, to create full-color OLEDs.

An OLED array of 40 x 40 dots at the resolution of 640ppi was realized and illuminated with UV rays to confirm that red, green and blue dots separately emitted light.

The emission of red, green and blue lights was also confirmed in a test involving the application of voltage rather than illumination, confirming its correct performance.

These results open new opportunities, such as using the novel photolithography in a multiple patterning process.

An example would be creating an OLED array that adds a fourth color to red, green and blue, as well as developing previously-unseen devices such as a new sensors that integrate OLED with the organic photodetector.

Electronics Weekly

Electronics Weekly