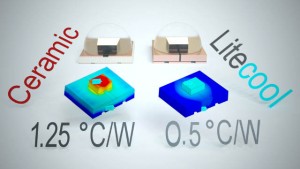

Dielectric layers are essential to separate electrical conductors but, with a few notable exceptions like diamond, introduce thermal barriers.

Spreading heat before it reaches insulating layers with a thick thermal conductor like copper increases heat flow through subsequent insulating layers.

Litecool’s technique “has significant benefits for flip-chip packaging where dielectric layers are usually very close to the diode”, it claims. “Vertical dielectric technology allows for close packaging of multiple LEDs within one package with minimal effect on thermal performance.”

The concept, which is patent-pending, gets thick copper right up to the metal contacts on the LED package and is simple in concept, but stepping away from the 2D insulating layers usually seen in PCBs and reliably creating 3D dielectric structures is not so straight forward.

“It is not a difficult concept to design but it is difficult to manufacture. We have had to develop new manufacturing processes to allow for the track and gap ratios required, and it has resulted in performance way beyond anything else on the market,” said Litecool project engineer Robert Corbin.

An additional benefit is that the pressure to select dielectrics for reduced thermal resistance – ceramics are usually chosen – is eased. “Cheaper polymer based dielectrics can be used as their thermal impact is negated,” said Litecool.

See also: The Electorincs Weekly LED blog – LED Luminaries

Electronics Weekly

Electronics Weekly