Called S16835, there are two models, which differ in the width* of their sensors: 54µm or 100µm.

In standard operating conditions (25°C ambient, -20°C SPAD) typical dark currents are 15 or 60 count/s respectively (50 or 200 count/s max).

Terminal capacitance and gain are 2.8pF and 6×106, or 3.2pF and 1.5×107, again respectively.

Photo detection efficiency including after-pulses is 67% in both cases and the sensitive spectrum is 400 to 1,000nm (visible and near-infrared) peaking at 610nm.

“These features make them ideal for a variety of applications such as low-light-level measurement, particle diameter measurement, fluorescence measurement, and analytical instruments,” according to the company.

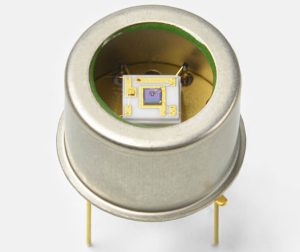

The packages are 14mm diameter TO-8 metal cans with a borosilicate glass window, and inside is the SPAD, a two-stage thermoelectric cooler and a thermistor.

SPAD breakdown voltage is 40V±5V, and recommended drive is at 7V over the breakdown voltage – at which the temperature coefficient is typically 45mV/°C.

Maximums for the cooler drive are 1A and 900mV – the current-voltage characteristic is near-linear up to these values.

Typically is will take ~430mA to get the SPAD to -20°C with +25°C ambient and a 3°C/W heatsink, at which thermistor resistance is typically 60kΩ – max allowable thermistor dissipation is 200μW.

Find the 100μm S16835 SPAD on this web page

*Hamamatsu literature frequently describes these dimensions as ‘area’, but the company has confirmed to Electronics Weekly that it is the measurement across the sensor.

Electronics Weekly

Electronics Weekly