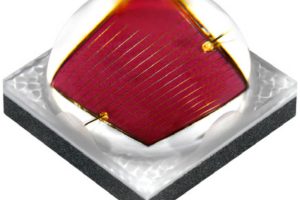

“Photobond OB4210 is characterised by its yellowing stability at high temperatures” according to the company. “Manufacturers of automotive headlights can use it to realise optically sophisticated applications – the transparent characteristics make it hardly distinguishable from the lens material.”

Transparency is typically retained after a 500 hour storage at +140°C.

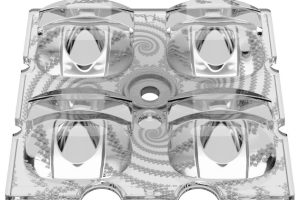

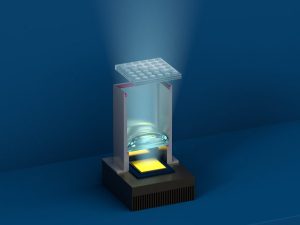

It is an acrylic adhesive with “near-instantaneous” UV curing (down to 1.5s), said Delo, suiting it to alignment of lens and other optical systems around matrix LEDs, microlens arrays and digital light-processing systems.

It can be used over -40 to +140°C and has a 35 MPa compression shear strength with polycarbonate, an optical material common in automotive lighting.

Low viscosity (3,000mPa-s) and flowability allow it to be used on larger surfaces.

The adhesive will be presented at the DVN conference in Shangha, which is over 4 and 5 December.

Electronics Weekly

Electronics Weekly