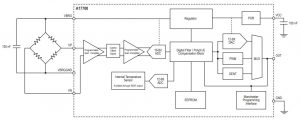

Called A17700, it amplifies and offset-adjusts the analogue input to best-fill the ADC for its internal digital signal processor.

DSP includes filtering to trade speed with noise, then compensation for pressure non-linearity and temperature using a polynomial function up to 4th order.

“The A17700 allows system designers to select the optimal algorithm and I/O options that best fit their system requirements, balancing accuracy and end-of-line test times,” said company product manager Haeyoung Choi.

Calibration parameters are stored in on-chip EEPROM that can be written 100 times.

Output is ratiometric analogue, digital SENT protocol or PWM.

Potential errors causing parameters are tracked. “Environmental conditions, such as a change in supply voltage level, temperature, input bridge signal and connection can cause temporary faults in pressure sensing systems,” accordng to the company. “The A17700 captures these changes and signals them in the output protocol, enabling fault filtering at the system level for more accurate safety notifications.”

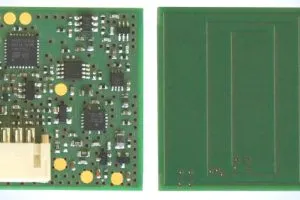

Packaging is 4 x 4mm 24pin QFN package with wettable flanks and exposed thermal pad.

Allegro sees it being used in dynamic brake systems, direct fuel injection, brake boosters, air conditioning and oil in automatic transmissions.

The A17700 product page is here and the application guide is clearly written and worth a look

Electronics Weekly

Electronics Weekly