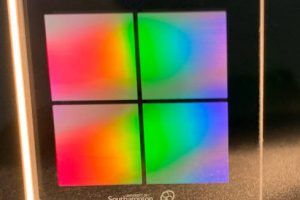

“At the moment a circular laser beam is used by Exitech with masks to throw away the energy that is not wanted,” said Southampton’s Professor David Richardson. “With the holey fibre we can make a square image on the work piece and reduce loss.”

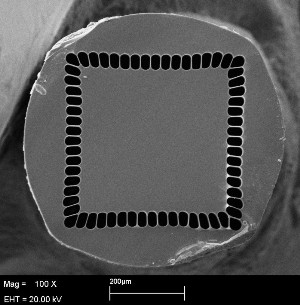

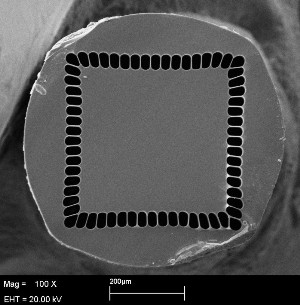

Holey fibres are a Southampton speciality. The holes act to reduce refractive index locally across the fibre in order to constrain light within it, and offers greater refractive index variation than the selective doping used in conventional optical fibres.

Energy entering the fibre is gradually herded into the desired shape by the holes. “You probably need about a metre to get a square beam,” said Richardson.

|

Once the beam leaves the fibre it diverges back into a circular pattern. To get the necessary square image, a lens at the end of the fibre focuses the beam directly onto the work piece.

The dimensions of holes and inter-hole support struts control the divergence of the beam as it leaves the fibre, and have been chosen to work with the lens to achieve the correct final image.

Fibres are made by heating and drawing down a Thermos flask-sized glass cylinder.

In this case the initial cylinder was designed and made by Southampton’s John Hayes who stacked glass rods in a square lattice and surrounded them with hollow capillaries. Around these were stacked a combination of more solid rods and some hollow rods.

“The capillaries are pressurised and expand during drawing,” said Hayes. “The hollow rods collapse and allow the expansion.”

Electronics Weekly

Electronics Weekly