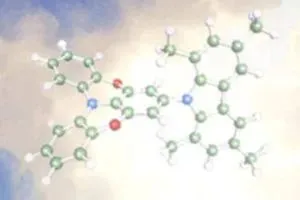

Under study were sodium-ion oxide cathodes made from transition-metal core-shell particles – a nickel-rich core surrounded by a cobalt and manganese-rich shell.

“The manganese-rich surface gives the particle its structural stability during charge-discharge cycling,” according to the lab. “The nickel-rich core provides high capacity for energy storage.”

Energy storage capacity steadily declined during cycling, which was narrowed down to cracks developing in the cathode particles due to strain arising between the shell and core in the particles.

Further work revealed that these cracks were initiated deep within the particles, and not, as had been expected, at the surface. It also revealed a way to stop the cracks.

The two sentences above bely the huge research effort required to make the discovery, which, amongst other equipment, required two of the world’s most powerful synchrotrons and, to understand their data, a world top-50 super-computer: Argonne’s Advanced Photon Source, Brookhaven National Laboratory’s National Synchrotron Light Source II and Argonne’s Polaris computer.

“Preventing cracks during cathode synthesis pays big dividends when the cathode is later charged and discharged,” said Argonne chemist Gui-Liang Xu (above).

Deceptively simple, crack-proof cathode particles, which had no loss of storage capacity over 400 operating cycles, resulted from a change in the heat treatment used to make them.

Core-shell cathode particles are made by heating hydroxide precursors at temperatures up to 600°C.

With a warming rate of 5°C/minute cracks initiated at the core and the core-shell boundary at as little as 250°C, while heating unusually slowly – at 1°C/minute – produced robust particles.

“The prospects seem very good for future sodium-ion batteries, with not only low cost and long life, but also energy density comparable to that of the lithium iron phosphate cathode now in many lithium-ion batteries. This would result in electric vehicles with good driving range,” said Argonne battery team lead Khalil Amine (right).

“The prospects seem very good for future sodium-ion batteries, with not only low cost and long life, but also energy density comparable to that of the lithium iron phosphate cathode now in many lithium-ion batteries. This would result in electric vehicles with good driving range,” said Argonne battery team lead Khalil Amine (right).

Future work planned at the lab includes an attempt to reduce cost and increase sustainability by eliminating nickel from the cathode.

US Government funding for Na-ion

The US Department of Energy has awarded $50m over five years to establish an entity called ‘LENS’ – the Low-cost Earth-abundant Na-ion Storage consortium.

To be led by Argonne, it will include Brookhaven, Lawrence Berkeley, Pacific Northwest and Sandia US national laboratories, and the SLAC National Accelerator Laboratory.

“The challenge ahead is improving sodium-ion energy density so that it first matches and then exceeds that of phosphate-based lithium-ion batteries while minimising and eliminating the use of all critical elements,” said consortium director Venkat Srinivasan, who also leads Argonne’s ‘Collaborative Center for Energy Storage Science. “Any improvements must not compromise other performance metrics such as cycle life and safety.”

LENS has eight university partners: Florida State University, University of California San Diego, University of Houston, University of Illinois Chicago, University of Maryland, University of Rhode Island, University of Wisconsin-Madison and Virginia Tech.

Details of the cathode research can be found in the Nature Nanotechnology paper ‘Microstrain screening towards defect-less layered transition metal oxide cathodes‘.

Electronics Weekly

Electronics Weekly