“It’s difficult to get commercial electronics integrated into these super thin structures,” said Illinois professor Xin Ning, who added that anything the team made had to be “able to withstand the harsh environment of space”.

Two years ago, Ning piqued the interest of NASA when he presented a paper on multi-functional space structures at a conference.

“It got the attention of Juan Fernandez from Langley Research Center,” said Ning. “He was making a boom structure for a Virginia Tech CubeSat project and saw the opportunity to collaborate.”

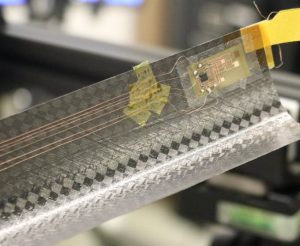

The final boom, made at Langley, is a three-ply carbon fiber and epoxy composite 156μm thick weighing 20g that rolls up and springs out like the tape in a tape measure.

Components were needed at its far end to help ensure that it deploys properly.

To start with, power and data lines were required along the entire 1m length.

“Eventually, we went with thin commercial wires coated with insulation and it worked,” Ning said. “I think we were over-thinking it at the beginning. We tried more difficult, fancier approaches, but they failed. This was a simple and reliable solution using off-the-shelf, readily available wires.”

Similar techniques were then used to fabricate electronics for the tip of the boom that could be roll-up, sprung out, and then survive in space.

In the package are: a motion sensor, a temperature sensor and a blue LED, allowing initial deployment and subsequent vibration to be monitored, and to help the satellite’s camera check the boom’s position.

The project has reached its goals for the Virginia Tech’s 2025 3U CubeSat launch. “We have tested the system in a thermal vacuum chamber and it worked,” Ning told Electronics Weekly. “The boom is already complete and ready to go.”

Along the way, a pool of expertise and data has been generated for future designs, and the team is has moved on to creating this next generation. “We are working on making the flexible electronics more durable in space – to protect the electronics so it will be operational longer,” said Ning.

‘Multifunctional bistable ultrathin composite booms with flexible electronics’ is a paper describing the research, published in Extreme Mechanics Letters.

Photo: The boom extended, carrying motion and temperature sensors, and an LED.

Electronics Weekly

Electronics Weekly