The proof-of-concept device has been made using techniques that could be scaled for production, according to Draper research engineer Gregg Favalora: “We can report the first demonstration, to our knowledge, of a scalable, monolithic surface-emitting electronic holographic modulator – an element of a 3D display that is made using standard microfab techniques.”

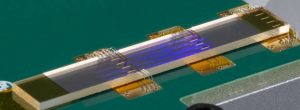

It consists of a strip of lithium niobate crystal 1mm thick that resembles a microscope slide (see photo).

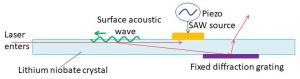

In operation, a laser beam is fed into the crystal just below its surface (diagram left), after which it continues to travel just below the surface.

In operation, a laser beam is fed into the crystal just below its surface (diagram left), after which it continues to travel just below the surface.

Meanwhile, surface acoustic waves are launched in the opposite direction, travelling as parallel clusters of faint surface ripples.

As beam and ripple cluster pass one another, the surface waves act as a moving diffraction grating, directing some of the laser energy downward into the thickness of the slide.

Here it would stay, bouncing back and fourth by total internal reflection – except Favalora and his team have deposited a fixed diffraction grating on the back of the crystal to direct the beam out of the top surface.

Both the exit angle of the laser and the exit position can be controlled.

The exit angle is set by the frequency of the SAW (280-320MHz, as well as the laser wavelength) because this controls the initial downward deflection angle.

The exit position is controlled by pulsing the laser, and varying the position at which it encounters the SAW pulse.

The length available for SAW-laser interaction in the prototype is 8mm, and the team has done various things within this including launch a string of SAW pulses, quickly enough for them all to reside in the 8mm at the same time, resulting in a single laser pulse producing a row of exit beams, or a string of SAW pulses at different frequencies producing a fan of exit beams.

“This is an early demonstration of an electro-holographic spatial light modulator device into which 8 mm of holographic fringes are loaded that can project a linear light field,” Favalora told Electronics Weekly. “This has many applications. For example: depending on the electronic signals applied to the modulator, light exits from programmable apertures, in programmable directions, with programmable luminance per direction. This is useful because the field of electronic holography, and digital print holography, has developed a variety of ways to use the surface of a hologram to project 3D imagery.”

‘Holographic’ here is used to describe the diffracting nature of the optics, and has nothing to do with the 3D display mentioned above. A simple fixed frequency SAW pulse acts as a diffraction grating, but a pulse with a complex waveform would cause other interferrences that would modify the beam in the same way a hologram affects light.

The sort of ‘3D’ display envisaged by Draper is not holographic but ‘autostereoscopic’ where, instead of wearing special glasses, the display is effectively a pair of projectors, one sending an image to a person’s left eye, and the other each sending a slightly different image to the person’s right eye. The images differ in the correct way to add ‘depth’ to the overall perceived image. In practice, autostereoscopic displays send out a horizontal fan of different images, and the viewer’s eyes pick up pairs of images from the fan – this is how 3D TVs of a few years ago worked.

“Many approaches to glasses-free autostereoscopic displays exist,” said Favalora, “but electronic holography is believed to offer the highest degree of realism and depth. However, commercially-available modulators are either: too complicated to manufacture, too small, have packaging so large that tiling them into larger areas [to create a large display] is not an option, or are made of discrete pixels that are too large compared to the wavelength of light to fine-tune angles in the light field.”

The Draper modulator addresses these requirements according to Favalora because it can be designed into wafers that can be tiled, and fabrication only requires a few simple steps.

Its output is also continuously-variable in angle and output position (at least in the plane of the diagram above), and so visual detail in that display plane and along the depth axis can be dialled-in by the hologram rendering algorithms, he said.

However, angular control is narrow – over only 0.3° in the prototype. Which the researchers “believe can be expanded to at least 1°, and further to 10° with wavelength-based coarse light field direction aiming, and further yet to 60° with the addition of field-of-view-expansion optics,” said Favalora.

This wavelength-based aiming exploits the effect the laser wavelength has over exit angle. For example, several lasers of different wavelength, all appearing ‘red’ to a human, could be sent through the crystal so cause major angle step changes in an exit beam, with SAW frequency tuning used for fine control between the steps, said Favalora. The same would be true of blue and green lasers in a colour display. “Other workers in the field have demonstrated RGB display from a different type of SAW modulator,” he added.

In a real display, the device in the diagram would be mounted so that it created a horizontal fan, and would be surrounded by identical devices – hence the requirement for tiling mentioned above.

The device in the photo is possibly a step along this road. Look closely to see 15 SAW transmitters – in a 5×3 array that would be mounted letter-box-style towards the viewer and produce five parallel light fans as well as two neighbouring stacks of five fans.

Above are only a few details of the proof-of-concept and potential 3D displays. For far more information, consult the associated paper:

‘Surface-emitting electroholographic SAW modulator‘ on Optics Express.

Favalora is leader of imaging systems at Draper, and chair for the 2020 Stereoscopic Displays and Applications Conference (27-29 January).

Electronics Weekly

Electronics Weekly