Modern, sophisticated applications, such as humanoid robots, require motor drives to deliver precise control over speed, torque and efficiency for electric motor applications. These systems have evolved significantly in recent decades and demand higher performance, smaller sizes and reduced losses. The industry’s transition from traditional silicon-based inverters to advanced GaN devices has unlocked new potential for high-frequency operation, bringing unparalleled benefits to motor drives.

Modern, sophisticated applications, such as humanoid robots, require motor drives to deliver precise control over speed, torque and efficiency for electric motor applications. These systems have evolved significantly in recent decades and demand higher performance, smaller sizes and reduced losses. The industry’s transition from traditional silicon-based inverters to advanced GaN devices has unlocked new potential for high-frequency operation, bringing unparalleled benefits to motor drives.

High-frequency operation is increasingly essential for motor drive systems, enabling smoother, more efficient and compact designs. Traditional silicon-based systems have limitations in switching speed, typically constrained to operating frequencies below 40kHz. GaN transistors, however, allow engineers to push these boundaries with switching frequencies exceeding 100kHz.

Benefits of high-frequency motor drives

* Reduced total harmonic distortion (THD): high-frequency switching improves the sinusoidal waveform of motor voltage and current. This reduces harmonic losses and enhances the motor’s overall efficiency. Lower THD also leads to quieter operation, making it an ideal choice for robotics and industrial automation.

* Compact filter design: high-frequency operation reduces the size of input and output filters. Unlike traditional systems requiring large electrolytic capacitors, high-frequency drives can use ceramic capacitors, cutting down on size, weight and cost, and improving reliability.

* Minimised dead time: high-frequency switching enabled by GaN reduces the dead time needed between switching events to prevent cross-conduction, minimising torque ripples and improving motor performance.

* Improved efficiency: high-frequency operation decreases motor losses. This is critical in battery-powered applications, where efficiency directly impacts runtime and performance.

* Better dynamics: higher switching frequencies allow faster response times in controlling motor speed and torque, leading to better performance in dynamic applications such as drones, e-bikes and robotics.

As motor drive applications push the boundaries of performance, GaN technology has emerged as the definitive solution. Traditional silicon mosfets cannot match the high-speed switching, low losses and compact size offered by GaN transistors.

GaN for motor drives

* Low switching losses: GaN devices have significantly lower switching losses than their silicon counterparts, making them efficient at higher frequencies. This translates to reduced heat generation and improved reliability in motor drive systems.

* High power density: GaN allows miniaturised inverters. Compact inverters are crucial for applications with limited space, such as drones, humanoid robots and personal mobility products.

* Elimination of reverse recovery losses: In hard-switching topologies, silicon devices suffer from reverse recovery losses. GaN transistors eliminate these losses, improving overall efficiency and enabling robust performance.

Design challenges

High-frequency motor drives offer significant advantages, but also present unique challenges.

* Thermal management: operating at higher frequencies generates more heat, which can affect system reliability. GaN transistors have superior thermal conductivity and lower switching losses to mitigate these thermal challenges. Optimised PCB layout, featuring efficient heat dissipation pathways and thermal vias further enhances cooling performance.

* EMI: high-frequency switching increases electromagnetic emissions, posing challenges for regulatory compliance. Integrating inverters directly within the motor reduces the physical distance of high-frequency components, further mitigating interference.

There are many examples of GaN in modern high-frequency motor drives.

Industrial and service robots, including humanoid robots, rely on efficient and precise motor drives to perform complex tasks. These robots often include multiple brushless DC motors, each requiring an individual inverter. GaN-based motor drives are suitable for these applications due to their high efficiency, compact size and ability to integrate into limited spaces within the robot. Furthermore, GaN’s high-frequency operation ensures smooth torque delivery and reduces heat generation, critical for robots performing continuous operations.

Another application is drones and unmanned aerial vehicles. These demand lightweight and efficient motor drives to maximise battery life and payload capacity. GaN inverters operating at high frequencies drastically improve motor efficiency, allowing drones to fly longer and carry more equipment. The reduced size and weight of GaN-based systems are also advantageous for these aerial applications, where every gram counts.

For industrial vehicles, from forklifts to power tools, GaN motor drives deliver higher efficiency and better control over motor speed and torque than silicon counterparts. The ability to handle high currents with reduced thermal losses makes GaN particularly suitable for rugged environments. GaN’s high-frequency operation reduces noise and vibrations, improving user comfort and safety.

Electric personal mobility devices are another use case. GaN inverters in modern e-bikes deliver higher efficiency and compact designs. By operating at higher PWM frequencies, these drives reduce input and output ripple, eliminating the need for bulky LC filters. The improved efficiency ensures longer battery life, while the reduced size and weight allow for seamless integration with the e-bike’s motor.

High-frequency operation in motor drives offers unmatched efficiency, performance and compactness. GaN technology’s superior switching speed, low losses and high power density mean it is positioned to meet the challenges of high-frequency motor drive design.

From drones to humanoid robots and industrial machinery, GaN-based motor drives are enabling quieter, more efficient and highly reliable systems.

As the demand for high-performance motor drives grows, GaN technology will remain at the forefront, powering the next generation of innovation in electric mobility, automation, and beyond.

Case study

As applications such as robotics, electric vehicles and industrial automation evolve, GaN allows applications to demand higher performance, efficiency and miniaturisation in motor drives.

As applications such as robotics, electric vehicles and industrial automation evolve, GaN allows applications to demand higher performance, efficiency and miniaturisation in motor drives.

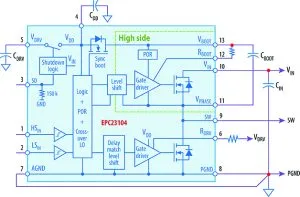

Innovations in GaN device design, such as integrated GaN power ICs will further simplify the adoption of high-frequency motor drives, reducing design complexity and cost.

The block diagram is an example of one of these devices, the EPC23104 ePower Stage IC.

Case study

GaN in high-performance robotics

humanoid walking side by side helping the elderly walk by guiding their hand in a retirement home

Humanoid robots, which feature dozens of multiple brushless DC (BLDC) motors for movement, present a compelling case for GaN technology. These robots demand compact, lightweight and efficient motor drives to achieve human-like mobility and extended operation times. Humanoid robots can use up to 40 BLDC motors to drive movements across joints, limbs and mechanical components.

Motors powering smaller joints require low current, while high-demand joints such as hips or legs need up to 150A. GaN inverters provide the necessary high-frequency operation to ensure smooth, precise control of each motor, enabling lifelike movements.

By reducing weight through integration and increasing efficiency, humanoid robots are able to perform complex tasks with greater accuracy and for more extended periods.

See also: Power content

Electronics Weekly

Electronics Weekly