The past year has seen a huge boost in the growth for wearable devices to diagnose and monitor patient health. The importance of remote patient monitoring (RPM) has become even more important in the wake of the Covid-19 pandemic.

Woman checking glucose level with a remote sensor and mobile phone, sensor checkup glucose levels without blood. Diabetes treatment.

Lockdowns, travel restrictions and the requirement for social distancing to slow the spread of Covid-19 have meant that digital health wearables and RPM have important roles to play.

RPM allows patients to use mobile electronic medical devices to gather health data so it can be easily recorded for healthcare professionals. This assists in moving medical management outside the hospital setting and reducing the burden on healthcare facilities. It also helps to prevent infection contamination, an area of particular importance during the pandemic.

Wearables are playing a significant role in contact tracing, tracking and monitoring the progression of Covid-19 symptoms and understanding and improving the world’s response. Market Research Future has predicted the wearable medical device market will grow from $7.86m in 2017 to more than $27.2m by 2023 with a 23% compound annual growth rate during the forecast period. The use of wearables to combat the towering costs of healthcare is the primary driver of the market.

These devices have been successful in the management of diseases such as asthma, diabetes and heart conditions. Other factors driving the market growth of wearable medical devices include the rise of lifestyle diseases, the cost-effectiveness of these devices and the rise of connected healthcare mobile applications.

The demand for digital wellness, remote monitoring and diagnostics means an increasing requirement to produce complex electronic components. These have ever-tighter tolerances to make them small, light and portable for the comfort and ease of use by the patient. Thanks to enhanced technology and the production of miniaturised circuits, the future is bright for wearables. There is, however, some shade being cast on their reliability if cleaning processes are not completed successfully as device failure could follow.

Cleaner boards = higher reliability

Functionality and efficiency are important qualities for all medical wearables. Improving the accuracy of a component such as a PBC can result in higher capability and consistency for these systems. Wearable medical devices must be manufactured without fault to meet the validation requirements, quality standards and regulations set by governing bodies. Effective cleaning is a significant part of this.

Several ready-made printed circuit boards are installed in a metal stand. Manufacture of electronic components.

The intricate, multi-faceted circuitry used within wearables requires high levels of cleaning to remove any contamination. Particulate, oils or inorganic contamination resulting from the manufacturing process should be precision cleaned.

Contaminated PCBs are vulnerable to a number of problems including shorting, delamination, electrochemical migration, parasitic leakage and dendrite growth.

PCBs used within wearable medical devices are small, densely packed and multi-layered. They are frequently designed with bottom termination components with low or zero clearance, making them extremely difficult to clean and rinse away contaminants.

The low stand-off between conductors collects and traps manufacturing contaminants such as solder balls and flux residue. In many cases active fluxes or flux residue may stay on the PCB after reflow in wave machines or after hand-soldering. Other contaminants, such as ink and fingerprints that require removal for optimal circuit board reliability present a challenge to manufacturers as they look for ways to ensure contamination is removed under and around these tightly-spaced components.

If cleaning is not completed effectively, product performance and reliability may be affected. The task is to identify a process that is suitable for the critical cleaning of complex assemblies, intricate shapes and delicate parts found within wearable devices.

Vapour degreasing

When it comes to cleaning medical wearables and the PCBs within them, the most efficient, effective and sustainable method is vapour degreasing.

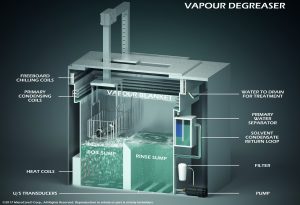

Vapour degreasers are composed of a closed-loop system. They are not only extremely capable and fast, but also very economical and flexible, making them suitable as a long-term option. They typically contain two chambers, the boil sump and the rinse sump. In the boil sump, the cleaning fluid is heated to boiling point and the parts are immersed and cleaned. Once cleaned, the parts are mechanically transferred to the rinse sump for final cleaning in a pure, uncontaminated fluid. The parts come out clean, dry, spot-free and immediately ready for the next step in the manufacturing process.

Vapour degreasers are easily adaptable with equipment options available to make the process even simpler and faster. The tanks where the cleaning fluid is stored can be fitted with filtration systems to remove insoluble particulate. They can also be equipped with ultrasonic energy transducers to enhance cleaning.

Automated hoists free operators from lifting parts in and out of the degreaser. This process offers consistency improvement while increasing throughput through autonomous methods. These automated cleaning processes are important as manufacturers look for practices which are not heavily reliant on human input.

Covid-19 is affecting and changing operational activity. With the constant possibility of members of the workforce having to self-isolate, and the risk to health and safety a top priority, automated system options are now integral to modern production processes.

External distillation and ‘super heat’, which ensure parts are completely dry before removing them from the vapour blanket, are economical and performance-enhancing choices. Depending on the application and process requirements, the technology exists to manage the largest parts and highest volumes. When properly designed, vapour degreasers can be considered the most adaptable precision cleaning process that will withstand future applications.

Getting to the bottom of it

Effective cleaning is essential when manufacturing medical devices. Not only does it have to remove particulate from complex parts with challenging geometries, but it must also address the regulatory requirements imposed by governing bodies within the medical manufacturing sector.

The non-flammable cleaning fluid used within a vapour degreaser is specifically designed to remove contaminants even from the most delicate and intricate parts, such as those used within wearable products.

The vapour degreasing fluids used to clean electronic medical devices are dense and this helps to dislodge particulates from the components. They have low viscosity and surface tension ratings that allow them to clean very effectively even in small gaps and areas that other cleaning methods cannot easily penetrate. The contaminants push away from the substrate and wash away, dispersing into the cleaning fluid. This ensures that all the surfaces of the finished component will be effectively cleaned, even in multi-layer boards and those with tight stand-off components.

The vapour degreasing fluids used to clean electronic medical devices are dense and this helps to dislodge particulates from the components. They have low viscosity and surface tension ratings that allow them to clean very effectively even in small gaps and areas that other cleaning methods cannot easily penetrate. The contaminants push away from the substrate and wash away, dispersing into the cleaning fluid. This ensures that all the surfaces of the finished component will be effectively cleaned, even in multi-layer boards and those with tight stand-off components.

Vapour degreasing fluids are also low-boiling, typically between 40˚C/105˚F and 65°C/165°F. This is particularly advantageous when cleaning fragile electronics as it helps minimise the risk of damage to wafers and other delicate components. They can accommodate many different types of applications. This allows removal of a particular soil from a specific substrate, helping to maximise cleaning effectiveness without substrate damage.

Another benefit of using vapour degreasing and modern cleaning fluid is the ability to dry components on every cycle. This reduces the risk of bioburden, an essential requirement when manufacturing medical devices.

Bioburden occurs when bacteria remain on a surface that has not been sterilised effectively. Any moisture that remains in hard-to-reach areas can encourage the growth of bacteria. If it is not properly addressed, it can result in increased complications during the validation of the product and issues with the reliability of the device. Cleaning fluids in a vapour degreaser are hostile to pyrogens and will minimise the bioburden risk. Because PCBs come out of the vapour degreaser clean, dry, spot-free and cool enough for immediate coating or packaging, the possibility of bioburden contamination is reduced considerably as any moisture is removed. Vapour degreasing also makes it easier to validate to the new EU 2017/745 or EU MDR requirements that are going into effect regulating medical devices.

Consistent cleaning

Medical wearables, by their very nature, are challenging to manufacture. PCBs are the backbone of electronic wearables, consequently their reliability is a priority. Their small size and dimensions however make them particularly challenging to clean.

Cleaning is an essential step in the manufacture of wearables to remove any contaminant that can affect its long-term functionality. The cleaning method used may impact the longevity and reliability of the device. It is therefore important to find cleaning processes that remove every contaminant from every part of the high-density PCBs used within them.

Added to the cleaning challenge is finding a process that is also effective at drying. Bioburden is a reliability and regulatory risk and must be controlled at all costs. Vapour degreasing and the use of modern cleaning fluids address all of these concerns. It is an efficient and effective process that cleans and dries medical components thoroughly to ensure longevity of the device. For medical wearables to continue to grow and for the technology to advance, reliability is not only important but critical. PCB cleaning is a huge part of its future success and the answer to its consistency.

Electronics Weekly

Electronics Weekly