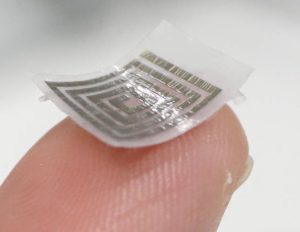

While many elastic or stretchable conductors are based on serpentine tracks, this one is based on micro-wrinkles in the conductive film, much like the patterns on fingerprints, but far smaller – too small to be seen in the photo.

The wrinkles start as a flat sheet of elastomeric polymer on a carrier wafer which is soaked in a solvent to make it expand slightly.

When a thin layer of polymer is deposited on this, wrinkles form once the solvent has gone, creating a suitable substrate on which to deposit the wrinkly conductive layer.

In practice the wrinkled conductive layer is pattered to to suit its electrical functions, and additional elastomer and polymer layers can be added to control the way movement and force reach the conductive layer, and to impart bio-compatibility.

The finished conductive film has “extreme resilience to bending and folding without fracturing the metallic pathways within, whilst also providing scalable manufacturing via semiconductor processing techniques as sensors are fabricated on silicon carrier wafers and are later peeled off to leave the thin flexible devices”, Edinburgh researcher Philip Hands (left) told Electronics Weekly.

The finished conductive film has “extreme resilience to bending and folding without fracturing the metallic pathways within, whilst also providing scalable manufacturing via semiconductor processing techniques as sensors are fabricated on silicon carrier wafers and are later peeled off to leave the thin flexible devices”, Edinburgh researcher Philip Hands (left) told Electronics Weekly.

The team has been funded by Scottish Enterprise to develop a sensor for use under therapeutic pressure stocking using the technology.

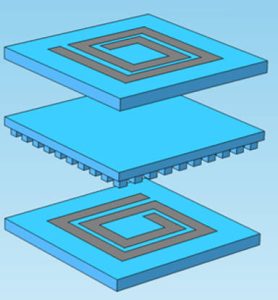

The result is a device (right) that has two of the crinkled layers pattered into spiral tracks, separated by a spongy layer whose compressibility is controlled by the intrinsic properties of the elastomer used and patterns embossed into its surface.

The result is a device (right) that has two of the crinkled layers pattered into spiral tracks, separated by a spongy layer whose compressibility is controlled by the intrinsic properties of the elastomer used and patterns embossed into its surface.

Once assembled, the whole patch is under 0.1mm thick – thinner than existing sensors – and can survive being bent back on itself around a 1mm rod. Test have extended to 1,800 bending cycles.

The two spirals are inductors, and pressure squashes them together increasing capacitance between them.

Connections (not shown in the diagram) are such that the whole thing forms an isolated LCR network whose resonant frequency changes predictably with pressure – with resonance measured by a nearby reader through inductive coupling.

“Different interrogation techniques are being explored, but our reader system currently provides a rapid frequency sweep, and measures the reflection coefficient of the interrogating signal at each frequency,” said Hands. “Our software calculates the resonance frequency compared to the uncompressed state, compares this to a pre-calibrated data set, and informs the user of the pressure currently being applied.”

For reading several local pressures at once, a set of sensors is planned with different resonant frequencies.

“As sensors are manufacturable to high tolerances, we anticipate calibration to be an infrequent and non-onerous requirement,” said Hands. “For improved accuracy, a sensor might also be quickly measured in the uncompressed state before use.”

Is it easy to use?

Yes, said Hands. Clinicians must already have training to fit compression garments consistently correctly, and the patch or patches need only be applied directly to the skin before this.

“The indicator to the clinician could be a simple message of the need to tighten or loosen in each area, requiring minimal training or skill,” he said. “It could feasibly even be used by the patients themselves, allowing for at-home monitoring.”

The University of Edinburgh worked with Heriot-Watt University on this project. It is being patented (search WO2021171037A1 for more information), and promoted commercially by Edinburgh Innovations, part of the University of Edinburgh.

A swallowable gastrointestinal pressure sensor has also being developed.

Electronics Weekly

Electronics Weekly