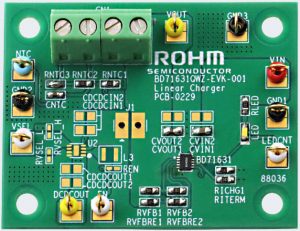

Called BD71631QWZ, it is a general purpose linear chip that can be powered from 2.9 to 5.5V and be resistor-programmed to deliver from 2 to 4.7V.

“In recent years the need for safer, higher density rechargeable batteries has led to the development of new battery types,” according to the company. “This includes all-solid and semi-solid types models using novel materials for the electrode part and batteries that adopt different terminal compositions. However, many of the latest rechargeable batteries are small and thin, requiring low voltage charging in the 2V to 3V range – there are currently no battery charger ICs that can handle a wide voltage range.”

Max charge current is 300mA (Vin≥4V, Vin-Vout≥1V), 100mA (Vin≥4V) or 30mA (2.9≤Vin≤5.5V), with minimum always 1mA.

A sophisticated multi-resistor-programmable algorithm is built in for constant-current-constant-voltage charging, with adjustable charge termination ( 50μA to 10mA) and re-charge threshold.

The chip disconnects voltage-sensing resistor pairs to prevent draining the attached battery when it is not being charged. Maximum drain is 1μA according to the company, and typical drain is “0μA”.

Additional protection functions include a fixed 10hour safety timer, under-voltage lock-out, thermal shut-down and battery over-voltage.

An evaluation kit (BD71631QWZ-EVK-001, photo above) is available, configured to charge a 4.2V lithium ion battery from 5V.

A charger design (REFLVBMS001-EVK-001), including demonstration hardware, is available for NGK’s novel EnerCera rechargeable ceramic cells.

Electronics Weekly

Electronics Weekly