“By expanding the selection of stability levels to include 50ppb and 100ppb versions, we’re able to supply with shorter lead times and at lower cost,” said Q-Tech v-p of marketing Scott Sentz.

The list of options is now:

- ±10ppb, 0 to +70°C

- ±20ppb, -40 to +85°C

- ±30ppb, -40 to +85°C

- ±50ppb, 0 to +70°C

- ±50ppb, -40 to +85°C

- ±100ppb, -40 to +85°C

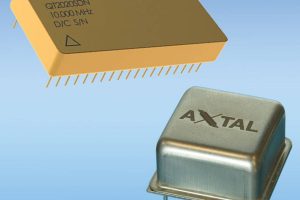

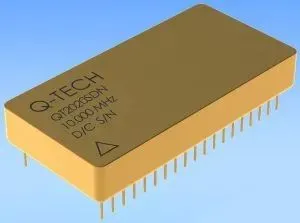

The difference in the two series is that QT2020 is rated for 29MeV/cm2/mg minimum single-event latch-up (SEL), while minimum SEL for QT2021 is 75MeV/cm2/mg. “QT2021 is designed to be single event latch-up immune and can be used for full space missions,” according to the company.

Total ionising dose (TID) tolerance in both ranges is 50kRad(Si).

The oscillators have 1pulse/s inputs and outputs, and come in standard frequencies of 10, 20, 30, 40, 50, 60, 80 and 100MHz.

Output choice is CMOS or sine wave logic.

Aging is ±1.0ppb/day, ±1.0ppm/decade and ±1.5ppm in 20 years – except in ‘breadboard’ grade non-space versions which score ±1.5ppm over 5 years.

Maximum power consumption is 90mW from 3.3V, and to save power they can be cycled as some parts can achieve ±50ppm accuracy in 1.5s, said Q-Tech, and it is “as little as 15s from power on to full ppb performance”. The later is over-temperature and for QT2021 parts – this time rises to 30s for QT2020 types.

Acceleration sensitivity is 1ppb/g.

The through-hole package measures 50.8 x 25.4mm, and extends 8.4mm above the PCB. Mass is 50g.

Find the “SEL immune” QT2021 series on this Q-Tech website data sheet

The company initially announce these series and its Axiom75Sx OCXOs at last years IMS

Electronics Weekly

Electronics Weekly