“The devices are designed for reliable operation in wet areas and during intensive cleaning processes and have protection classes such as IP67, IP68 and IP69K, as well as Ecolab, CleanProof+ and Diversey certifications.

There are retro-reflective sensors which send out light that is expected to hit a reflector target and return to the sensor. LED versions work up to 14m at 1.5kHz and laser version up to 20m at 2.5kHz. Special types can detect transparent objects at 3m.

‘Diffuse’ sensors do something similar, except they detect objects that do not include specialist reflectors. These operate at up to 1.2m and switch at 1kHz for LED types and 2.5kHz for the laser version.

‘Throughbeam’ sensors that are used in transmit-receive pairs when the path is interrupted by objects. These operate at ranges up to 30m and switch at 1.5kHz.

There there are more specialised types including sensors with automatic threshold adjustment against contamination, sensors with background light suppression, sensors with oval beams to simplify reliable counting of objects that have holes in them, and more.

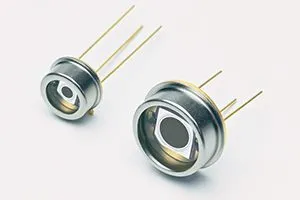

Series 33C sensors are aimed at hygiene-sensitive applications in food, beverage and pharmaceutical industries, even near unpackaged products. They have smooth housings without fastening holes. Instead, the sensors mount with a spigot that allows a gas-tight connection between sensor and machine.

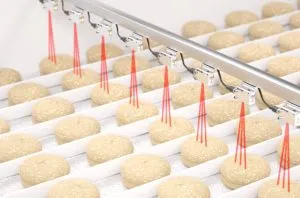

Series 35C sensors (example left) are for primary packaging of baked goods, confectionery and dairy products, and secondary packaging, machine tools and the automotive industry. Their enclosures can withstand high mechanical loads and intensive cleaning, and are completely waterproof and dust-proof.

Series 35C sensors (example left) are for primary packaging of baked goods, confectionery and dairy products, and secondary packaging, machine tools and the automotive industry. Their enclosures can withstand high mechanical loads and intensive cleaning, and are completely waterproof and dust-proof.

“The requirements for sensors installed above open foodstuffs are very high,” according to the company. “Only components authorised for contact with food may be used. The 35C series’ DRT35C dynamic reference diffuse sensor is the ideal choice for this. The PRK33C.PPTT3 retro-reflective photoelectric sensor is suitable for detecting transparent bottles in an aseptic filling line.”

“The requirements for sensors installed above open foodstuffs are very high,” according to the company. “Only components authorised for contact with food may be used. The 35C series’ DRT35C dynamic reference diffuse sensor is the ideal choice for this. The PRK33C.PPTT3 retro-reflective photoelectric sensor is suitable for detecting transparent bottles in an aseptic filling line.”

IO-Link is the chosen interface standard.

Electronics Weekly

Electronics Weekly