Over the past five years, many suppliers have acquired disparate types of sensor companies and are now consolidating technologies and narrowing their portfolios. As a result, certain parts are now being made obsolete or are entering into last-time buys at an elevated price. Digitisation is also having a major impact on manufacturing structures. In some respects, this is causing less flexibility for customers but, on the other hand, there are a lot of exciting new products coming to market.

Possibly the largest growth has been in digital sensors that consume very low power and are small. One particular area of interest for these sensors is automotive and more specifically the combined use of different sensor technologies, known as sensor fusion, is supporting battery management systems (BMS) and the entire drivetrain in electric vehicles (EV).

EV battery voltages

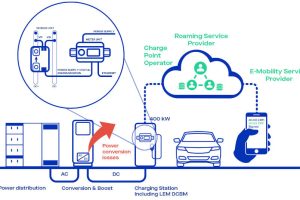

While most of today’s EV battery architectures are 400V, the heat generated by the latest DC fast chargers can overheat the batteries, which is one of the reasons why charge speeds tend to drop after 80%. To unlock significantly faster charging speeds, OEMs have moved to 800V architectures, which means that the battery receives more power from the charger but at a lower current. The lower current reduces resistance losses, thereby improving thermal efficiency and stopping the battery from potentially overheating.

There is also a benefit at the EV charging point. The charging cables can be of the same thickness since only the voltage increases, not the current, reducing cable cooling requirements.

EV powertrains

Other EV powertrain trends include range extension, which can be significantly enhanced by developing an efficient and effective BMS that dynamically balances the cells while the car is being driven and charged. EV batteries have a very slender ideal operating temperature window of between 20°C and 40°C. Temperatures outside that range can have a big impact on battery degradation and reduce the EV’s range.

Another element to consider is safety. If the battery runs too hot, the chemical reactions within the battery accelerate, which could ultimately lead to thermal runaway.

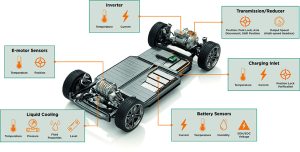

Advances towards smarter, more efficient and safer critical systems are made possible by sensors. The most common sensor types used within the EV powertrain are for monitoring temperature, pressure, position, fluid properties, fluid level, gas concentration, current and speed.

There are key application areas where sensors can be applied to the vehicle to ensure it operates safely and to prolong the battery life.

A second area for attention is thermal runaway. If the battery cells exceed the allowable operating temperature, they could catch fire or, worse, explode. When this occurs, the fire can propagate and spread to other cells within the battery pack. This is called thermal runaway.

The first is the battery pack. EV battery packs are complex and design and layout differ widely, according to the OEM. Generally speaking, they consist of a cluster of individual batteries, each containing hundreds of cells connected together. Battery pack condition monitoring is essential to check the overall state of health of the battery. Temperature sensors are attached to the outer casing to monitor the overall thermal performance of the battery pack, ensuring it remains within the safe thermal limits.

The chief causes of thermal runaway include a short circuit, both internal and external, over charging/discharging, external heating or self-heating. The primary indicators for cell failure are loss of cell voltage, heat generation, gas generation, build-up of internal gas pressure, swelling of the cell and smoke generation.

Temperature sensors monitor the cells and pressure sensors detect transient increases in pack pressure as cell gases vent into the battery pack environment. Gas sensors, including H₂ and CO₂ sensors, are used to detect gas emissions and particulate sensors detect smoke.

Cell connection system

Used as the top cover of the battery cell, the cell connection system provides connectivity BMS. Here, temperature sensors are used to ensure that the system is operating within the defined temperature limits.

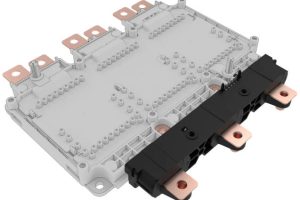

In the power inverter/electric motor, the high voltage DC from the battery must be converted to low voltage AC to drive the electric motor. Here, a combination of temperature sensors for thermal management and current sensors for applications such as overload protection is needed. In addition, high-speed rotary inductive position sensors are used to accurately measure the rotor position to efficiently drive the EV traction motor.

During charging, a combination of temperature and current sensors are used to ensure that it does not overload or overcharge and that the connector does not overheat. In addition, a position lock verification sensor is used to confirm a secure connection.

Protecting wire windings

Within the motor, wire coils generate a magnetic field and conduct electric current. The interaction between the two rotates the motor’s shaft, thereby converting electrical energy into mechanical energy. Here, temperature sensors are interlaced into the wire windings to ensure that the motor is operating within defined thermal limits.

Powerful rechargeable battery forklift. On the surface of the battery is an electrical connector.

Finally, within the vehicle’s battery, coolant circulates around the battery cells and temperature sensors. Pressure sensors and ultrasonic level sensors are used to maintain the battery’s optimum temperature. Additionally, combined temperature and pressure sensors provide both pressure and temperature measurements in one assembly.

As the sensor industry is consolidated and technologies change from analogue to digital, engineers may look to a variety of sensor suppliers and may seek custom designs to meet specific architectures or technical advice on integrating sensors effectively and efficiently into an integrated and complex system.

Electronics Weekly

Electronics Weekly