The IEA’s latest Global EV Outlook report reveals a surge in electric vehicle (EV) sales, which are projected to reach a staggering 17 million units by the end of 2024. This marks a significant milestone in the automotive industry as EVs are expected to constitute more than one in five cars sold worldwide.

The IEA’s latest Global EV Outlook report reveals a surge in electric vehicle (EV) sales, which are projected to reach a staggering 17 million units by the end of 2024. This marks a significant milestone in the automotive industry as EVs are expected to constitute more than one in five cars sold worldwide.

The critical role of advanced connector technology in sustaining this growth is becoming increasingly evident. The functionality of an EV allows it to efficiently manage and distribute power and it is heavily reliant on the quality and performance of its connectors. Connectors in EVs are not just simple links; they are sophisticated components that must meet stringent requirements to ensure optimal performance and safety.

Key requirements for EVs

EV connectors must handle high current loads to support fast charging and high-power applications. High current loads generate significant heat, which can lead to overheating and may risk potential failure of the connector if not properly managed.

Connector manufacturers need to use materials with high electrical conductivity, such as copper or silver alloys to minimise resistance and heat generation. They also need to incorporate design features, such as robust contact interfaces and low contact resistance, to support high current flow without significant energy loss.

Similarly, connectors must facilitate minimal power loss and ensure efficient transmission of electricity from the battery to various components of the vehicle. Power losses during transmission can reduce the overall efficiency of the vehicle and decrease its range. In this case connectors need to be designed with low contact resistance and incorporate thermal management features to dissipate heat effectively and maintain optimal operating temperatures.

Ensuring proper electrical insulation is also crucial for connectors in EVs to prevent short circuits, electrical arcing and other electrical failures. Connectors need to be made from high-grade thermoplastic materials, such as polyethylene or polytetrafluoroethylene that can withstand high voltages and harsh conditions.

They also need to incorporate design features that provide physical barriers between conductive parts to prevent accidental contact and arcing. At the same time they must be compliant with stringent safety standards and certifications, such as IEC 61851-1, IEC 61851-23 and IEC 62196, that regulate electrical requirements.

Connectors must also be able to adapt to the harsh conditions that the EV is exposed to. This includes working with extreme temperatures, moisture, dust and vibrations, without compromising performance. They must be compliant with different environmental regulations, such as REACH (Restriction of Hazardous Substances) and RoHS (Registration, Evaluation, Authorization and Restriction of Chemicals).

Connector technologies

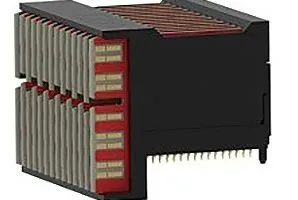

Advanced connector technologies enable efficient power management, crucial for maximising the range and efficiency of EVs. For example, Amphenol’s SurLok Plus line of connectors is specifically designed to enhance the performance, reliability and safety of EVs.

These connectors are used mainly in the battery pack of EVs and have a small footprint to allow easier system integration. A 1,500V range has been specifically designed for EV applications being developed. The connectors are IP67-rated (mated) to ensure protection against dust and water and have an integral latching system to ensure electrical and mechanical connection.

Military connectors

According to research group Cocoon, the US Department of Defense spends approximately $20bn on corrosion maintenance annually. In the case of electrical connectors, which are responsible for providing power, signal and data to military systems and heavy industrial vehicles, a great deal of research has gone into making them corrosion-resistant.

Both military ground vehicles deployed in desert operations and heavy, off-road and construction vehicles face extreme environmental challenges, including scorching daytime temperatures, cold nights and abrasive sand that can degrade their components. Shifting to coastal areas introduces high humidity and salt air, accelerating corrosion, especially on electrical connectors critical for operation.

For decades the defence and heavy industrial sectors have relied on connector-plating technologies to ensure the durability and reliability of electronic and communication devices in harsh environments. Historically, olive drab cadmium plating has been the standard for the military, prized for its corrosion resistance and electrical conductivity. However, cadmium’s environmental and potential health risks have prompted a search for safer, yet equally effective alternatives.

According to the scientific paper ‘Electrodeposition, characterization and corrosion investigations of galvanic tin-zinc layers from pyrophosphate baths’, tin zinc alloy deposits are recognised as alternatives to cadmium coatings due to their outstanding corrosion resistance. These coatings combine the barrier protection of tin with the galvanic protection of zinc.

Environmental conditions

Tin zinc J plating can withstand harsh environmental conditions and is rated with a corrosion resistance of more than 500 hours of static/five days of cyclic salt spray endurance as per VG test standards. This resilience ensures that connectors can endure the rigours of extreme weather, exposure to corrosive substances, and the wear and tear of rugged terrain, extending the lifespan of military equipment and heavy machinery while reducing maintenance needs.

The plating also offers high conductivity with a resistance of < 5mΩ. This low resistance ensures a reliable flow of electric current, an essential attribute for maintaining operational integrity in critical communication, navigation and weapon systems.

Military-approved

Tin zinc J plating is the official VG (German military)-approved one-to-one replacement for cadmium. VG standards are detailed specifications defining requirements for defence industry products and processes. These standards cover aspects such as environmental resistance, durability and electrical performance, including requirements for connectors used in military applications.

Another benefit of using tin zinc J plating over cadmium is that it complies with RoHS and REACH regulations, meaning that it complies to current environmental standards.

Introduced by the EU in 2002, RoHS limits the use of certain hazardous substances in manufacturing, including lead, mercury, hexavalent chromium and cadmium, aiming to safeguard human health and the environment from toxic emissions during disposal and recycling.

REACH, effective from 1 June 2007, broadens this approach by regulating the production and use of chemical substances to mitigate their impact on health and the environment. It mandates the registration of chemicals used or imported into the EU in significant quantities with the European Chemicals Agency, applying not only to the chemicals used in the manufacturing of electrical and electronic equipment but all chemicals, enhancing safety and environmental standards industry-wide.

Compatibility

The backward compatibility of tin zinc J plating with existing cadmium and other platings simplifies maintenance and logistical operations. This compatibility ensures that upgrades to tin zinc J plating can be implemented without extensive system modifications, reducing logistical complexity. Furthermore, the enhanced durability and reduced maintenance needs of tin zinc J-plated connectors contribute to greater operational efficiency and readiness.

Military equipment needs to be designed with durability and quick deployment in mind. Patrols cannot afford equipment failure when in dangerous areas and lives are at stake. Similarly, heavy, off-road and construction vehicles come into daily contact with dust, sand and water. With this in mind, what would be a reliable connector to use in something like a ground vehicle?

Bayonet connectors are valued in military operations for their quick and secure locking mechanism, ensuring a reliable connection with a simple twist-and-lock action. This design minimises the risk of disconnection due to vibrations or impacts, and is highly resistant to sand and dust, crucial in dynamic and harsh environments.

Their robustness and ease of use under challenging conditions, such as in field operations where speed and reliability are paramount, make bayonet connectors ideal for maintaining operational integrity in military communications, power supply and electronic systems.

A tin zinc-plated bayonet connector would therefore provide a highly conductive, corrosion resistant, environmentally safe, secure and quick connection for a ground vehicle, adding to its operational readiness.

Electronics Weekly

Electronics Weekly