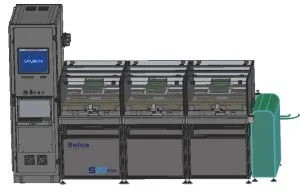

S20 IS3 (right) is intended to work with SiC and GaN as well as more conventional technologies, and is for ac and dc, static and dynamic testing.

“It performs accurate and repeatable characterisation of components such as IGBTs, mosfets and and diodes for R&D, production and quality control,” according to the company.

Static tests include on-state voltage, leakage currents and threshold voltage. Dynamic tests include turn-on and turn-off times, rise and fall times, and energy loss.

It has integrated high-level menu-driven software, and an oscilloscope. Test results are traceable.

S20 RTH (left) is the thermal resistance characterisation test bench. with advanced power and cooling management capabilities.

S20 RTH (left) is the thermal resistance characterisation test bench. with advanced power and cooling management capabilities.

“In modern power supply design, more and more attention is given to overall electrical efficiency and junction temperature,” said Seica. “This kind of test evaluates the thermal stress on power mosfet devices when they are used in switch mode power supplies. By computation with the physical characteristics of the device, it is possible to predict the temperature reached inside the junction, and the allowable margin or heatsink required to assure that the system has a suitable thermal margin during operation.”

It can handle loads up to 1,200A at 15 or 30V and the “power switching hardware enables a programmable controlled shutdown of the load current which minimises oscillations, allowing the system to perform measurements as soon as 80μs after the high current shut-down”, it said.

Configurations start at two devices-under-test an go up to 12.

The temperature, flow and pressure of the coolant to each tested device is automatically controlled by the system – up to 120°C and 100 litre/min.

Find the testers in hall 4 stand 235 at PCIM between 6 and 8 May in Nuremberg Germany.

Seica is based in Strambino, Italy.

Electronics Weekly

Electronics Weekly