Under the umbrella of C4ISR (command, control, communications, computers, intelligence, surveillance and reconnaissance) the development of sensors in the area of military aircraft is accelerating. The time between sensing and response, in particular,

Under the umbrella of C4ISR (command, control, communications, computers, intelligence, surveillance and reconnaissance) the development of sensors in the area of military aircraft is accelerating. The time between sensing and response, in particular,

is critical.

Whether radar or lidar applications, hyper- and multi-spectral imaging or quantum sensing, the amount of data being processed is constantly increasing. As data cannot always be sorted where it is produced, the need for better and faster high-speed networks onboard an aircraft becomes increasingly clear.

Optical fibre networks

Optical fibre networks are lighter than copper solutions and can deal with the speeds required in the foreseeable future. But connectors are the necessary evil in fibre networks.

Each interface drives up the optical link budget. Each is a potential area of failure due to environmental conditions such as pollution, temperature, vibration and humidity. If not properly serviced, the lifetime of these interfaces can be underwhelming.

Fibre solutions are already costly at the time of installation, but the overall lifetime cost in order to keep them operational exceeds these initial costs many times over.

A history of rugged fibre connectors

Initial systems used 38999 circular connector housings and equipped them with discrete fibres. These initial steps into fibre connectivity worked, but the connectors were simply too large.

About 20 years ago this changed with the introduction of a new fibre ferrule for the aerospace market. This MT ferrule derived from MTP or MPO connectors, which were originally designed for connecting servers in big data centres. It meant that it was possible to shrink the size of rugged fibre connectors drastically. This came at a price, however.

This MT ferrule was never designed for a harsh and rugged environment with many mating cycles and therefore has a very high sensitivity to dust and dirt. It needs to be cleaned before every mating cycle. Even so, the connectors are limited to a few hundred mating cycles. This is a huge price to pay for a much smaller solution.

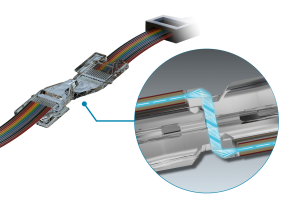

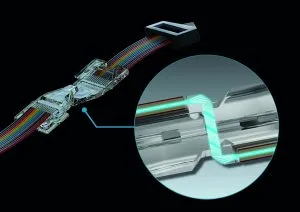

The light transmission path of an expanded beam technology connector

With both discrete fibre or MT ferrule the industry also had the choice between physical contact connection or expanded beam solutions based on lenses. While the physical contact solutions were relatively low loss budget, they needed even more maintenance efforts such as polishing the interface regularly. The expanded beam version had some better characteristics in terms of maintenance, but the insertion loss is not acceptable in most applications.

A few years ago 3M introduced a new fibre interface design. While originally designed for large data centres this expanded beam optical design addresses all the shortcomings experienced by the industry today. It is even slightly smaller than known MT ferrules.

The design combines a high insensitivity to dust and dirt with excellent insertion and return loss values that outshine even existing physical contact models.

ODU is the first company to ruggedise this technology for aerospace requirements and to introduce expanded beam performance products. They use an expanded beam contact technology for the transmission of light signals and are available in single- and multi-mode models.

At the heart of the new portfolio is a cassette system that allows multiple ferrules to be arranged side by side in a space-saving manner. With 12 connected fibres per ferrule, this allows for up to 96 optical fibres to be connected in a single connector.

The durability is claimed to exceed ferrules that are currently available on the market. The scattering of the light by using expanded beam technology eliminates the high maintenance costs typical for physical contact technology.

The temperature range is -65˚C to +105˚C; a very good transmission profile even under high humidity. The EBO connectors offer good vibration resistance.

Expanded beam performance

Beam expansion via a special lens transmits the light error-free from one contact to the lens of the contact in the counterpart for reliable, interference-free transmission even under adverse conditions.

As there is no direct contact between the contact ends, connections are insensitive to soiling and are easy to clean. No cleaning is required under normal conditions.

* High mating cycles (at least 50,000)

* Low insertion loss of <0.15dB (typical) for multi-mode and <0.35dB (typical) for single-mode connectors.

* Low return loss of >45dB (typical) and >60dB (typical) for multi- and single-mode respectively.

Models using EBO

ODU Tactics is a circular connector based on the upcoming VITA 95 standard. Available in four sizes within MIL-DTL-38999, Series lll housings with up to 96 optical fibres can be connected, depending on the configuration. It is offered as a low maintenance alternative to products based on MT ferrules (for example, VITA 87).

The AMC Series T is an alternative to the standardised MIL-DTL-38999 Series lll connector. Couplings are available in the square flange design, or as a jam nut version. Four shell sizes are available for up to 24, 48, 72 or 96 fibres.

The AMC Series T is an alternative to the standardised MIL-DTL-38999 Series lll connector. Couplings are available in the square flange design, or as a jam nut version. Four shell sizes are available for up to 24, 48, 72 or 96 fibres.

Electronics Weekly

Electronics Weekly