Reducing the weight of connectors and cables in applications such as aerospace, electric vehicles (EVs) and space systems is crucial for enhancing performance, fuel efficiency and overall system reliability.

Reducing the weight of connectors and cables in applications such as aerospace, electric vehicles (EVs) and space systems is crucial for enhancing performance, fuel efficiency and overall system reliability.

Connectors are generally heavier than other components such as chips and passives, which means they come under particular scrutiny in applications that demand low-cost operation, and where fuel expenses – not to mention the size and weight of the fuel tank – are inextricably linked to overall vehicle weight and, thus,

commercial viability.

The same imperative for weight reduction can be found in uncrewed aerial vehicles (UAVs) or drones that have a fixed power source (a battery) and where every gram of weight saved extends flight time. Similarly, EVs’ demand that every component be analysed for potential weight reductions to support the goal of maximising single-charge range.

Weight loss plans

Technological advances that enable connector weight reduction include the use of advanced materials such as high-strength, lightweight composites, aluminium alloys and thermoplastics.

The greatest savings, however, come from design and manufacture that physically reduce connector and contact size and allow more interconnects in a given space. This means careful consideration of the thickness of materials, the design of contacts and the overall structure of the connectors, and engineering the connectors to eliminate excess material wherever possible while still meeting stringent requirements for reliability, vibration resistance and durability.

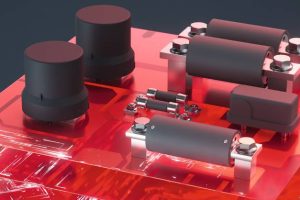

At the same time, connector designers are implementing alternative layouts featuring lighter and smaller interconnects with smaller pin pitches and enhanced electrical conductivity. Such layouts reduce weight but do not compromise on the reliability requirements found in areas such as satellites, UAVs and EVs (main image). Fine pitch enables use in space-constrained applications and smaller connectors are, by definition, lighter.

In recent years these material and design techniques have been brought together to create advanced connector technologies that are specifically designed for high-reliability applications where weight is a challenge. The most recent examples include high-performance, micro-miniature signal connectors that offer pitches down to just 1.25mm and are up to 75% lighter than more conventional Micro-D counterparts (see Fact File). Based on materials that have been specifically chosen for their strength-to-weight ratio, these connectors make use of lightweight, high-performance plastics for the connector housing and smaller gauge wires and contacts that are still robust enough to meet performance requirements yet reduce overall mass without compromising durability.

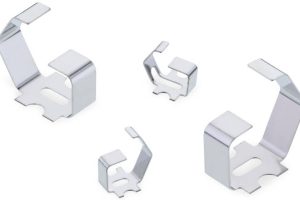

Furthermore, the use of advanced, high-reliability four-finger contact systems allow for secure connections with smaller, lighter components, while technologies that combine the fine-pitch signal connectors with power contacts can allow designers to eliminate some connectors, saving space, weight and cost.

Flex for further weight reduction

While many devices will be used for board-to-board interconnect, many more have been used to make board-to-cable connections, with the cables contributing a significant element of overall interconnect mass.

Pairing the latest micro-miniature connector technologies with flexible PCB technology – in which flexible films and thin layers of conductive material replace traditional wires – provides opportunities for further weight savings and enables a higher number of electrical connections in a given space.

Did you know?

New compact, high-density connectors feature:

* Pitch sizes down to 1.25mm

* Weight reductions of up to 75% compared to conventional Micro-D technologies

* Mixed signal and power options

* Four-finger contact designs maintain contact through high vibration and shock

* Wide operating temperature ranges (-65°C to +150°C).

Electronics Weekly

Electronics Weekly