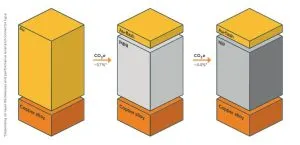

Branding the plating stack Econidur, “according to TE internal analysis and calculations, in alignment with ISO standard 14067/14040/44, CO2 emissions decrease over 44% compared to palladium nickel plating, depending on layer thicknesses, performance level and connector type”, said the company.

Is it robust?

“Econidur plated connectors will function reliably in many industrial applications over a long period of time – in automation control applications and motor control systems, for example”, said TE. “They support reliable signal transmission up to several Gbit/s and feature withstand capabilities in terms of vibration in the long-term, gas influences and micro friction. Overall, Econidur plating reaches in minimum the same characteristics as a precious metal plating layer. For fretting and vibration resistance, Econidur plated products are a reliable choice.”

Can you put a number on that?

“It is in minimum the same performance as currently used PdNi-plating,” the company told Electronics Weekly. “We pass 100,000 fretting cycles with Econidur.”

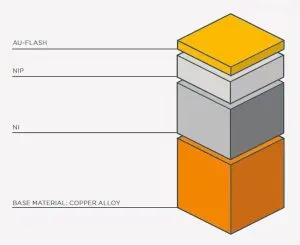

The top diagram is a simplification. The actual coating also has a layer of pure nickel (diagram left) under the nickel-phosphorus, both electro-plated.

The top diagram is a simplification. The actual coating also has a layer of pure nickel (diagram left) under the nickel-phosphorus, both electro-plated.

Electronics Weekly

Electronics Weekly