A touch more work over the weekend for the rev counter into a solid form that can be tried on the cnc lathe when it is re-assembled. Although some potential upgrades have been identified, the software is in a thoroughly usable condition. Find other Engineer in Wonderland cnc stuff here In the photo on the right, it is sitting in ...

cnc

The rev counter prototype is up and running

The cnc lathe rev counter prototype now works – with a bit of help from friends who can actually programme. On a signal generator, the display is rock-solid and spot-on – the crystal on the Arduino Pro Micro clone is doing its job. Find other CNC-related Engineer in Wonderland blogs here Attached to the perforated 48 hole synchronisation wheel output ...

Arduino reciprocal RPM meter progress

The parts arrived for the RPM meter that uses an Arduino and reciprocal counting to get a three-times-a-second update rate with 1rpm resolution. Arduinos plus ready-made modules are a very qick route to custom test gear, although this time the TM1637 based display module introduced a couple of spanners: Find other CNC-related Engineer in Wonderland blogs here Firstly, the ebay ...

CNC lathe: Big thanks to kind open-source folk

The cnc lathe project needs a controller to replace the 40 year old custom controller within the lathe. It is a shame this has to be done, as it was capable of automated thread cutting, which appears to be the holy grail of home-build cnc lathes. Find more on the cnc lathe project here The in-built controller might even still ...

No-volt release with few new holes?

Some sort of sane no-volt release and emergency stop needs to be applied to the cnc lathe project (when time allows….) And before that time is available, so thought has to go into what arrangement is acceptable. Find more cnc lathe project blogs here It seems a shame to cut too many more new holes in the front, and certainly ...

More detective work on the 1985 cnc lathe

A deeper dive into another board in the ancient cnc lathe revealed further quirks. The aim was to work out how the safety interlock worked – which uses the two relays on a board with digital logic and a big area with no components (photo). Find more cnc lathe project blogs here This took a while as there is a ...

Noise busting cnc probe circuit – New Improved?*

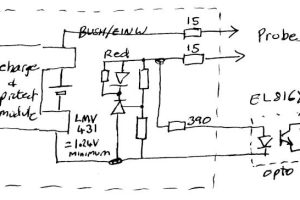

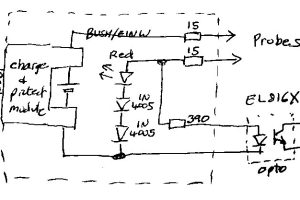

Pondering the good-enough isolated probing circuit I soldered up yesterday (repeated below), I wondered if there was a ‘100%’ clean alternative that was not much more complicated and would not have the slightly soggy, although acceptable, characteristics. (That said the led still gets brighter and dimmer when it is ‘on’, depending on cell voltage). Without making it – so bare ...

Noise busting cnc probe circuit

Following the connection of a new computer monitor, probing on one of the small CNCs packed up. Rather than find another monitor, a totally isolated probe was (probably not…) called for. One scrap bin raid later, and I came up with a 7 component isolated probe that has several attributes: Isolated open-collector output to processor board Provides some wetting current ...

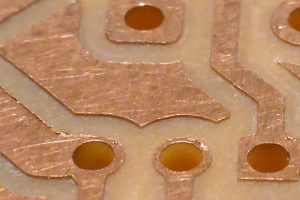

At last, an isolation routed pcb in Wonderland

Having spent years on and off trying to make a pcb using a cnc machine without breaking tool after tool, there was a minor triumph over the weekend (right). The test pcb is still not ‘right’ as an eccentricity in the (cheap) cutting bit collet (noticed afterwards) means that the tracks are ~0.2mm narrower than they should be – hence ...

Finally tried out the modified 1610Pro cnc, and it works delightfully

I finally found time to try out the home-modified 1610Pro desktop cnc. And here is the result: routed from 4mm thick cast Perspex with a 1mm deep letter ‘h’, all edges machined. The routed rectangular base is 27mm tall (as I remember) and is accurate to better than 100μm. The only error was 200μm in the total length of the ...

Electronics Weekly

Electronics Weekly