There are all sorts of amateur chemical rust removing techniques, and some electrochemical ones, many of which eat away lots of good metal as well as rust – all the dip-it-in-acid types, for example. Even ‘safe’ acids like vinegar and citric eat metal as well as rust. Commercial rust eaters have a mixture of chemicals (some well-guarded secrets) to dissolve ...

Engineer in Wonderland

CNC lathe rev counter prototype ready for action

A touch more work over the weekend for the rev counter into a solid form that can be tried on the cnc lathe when it is re-assembled. Although some potential upgrades have been identified, the software is in a thoroughly usable condition. Find other Engineer in Wonderland cnc stuff here In the photo on the right, it is sitting in ...

Weigh a flying plane from the ground

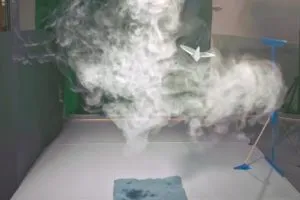

Mechanical stuff never ceases to amaze me. The latest revelation is that one can weigh an aeroplane flying overhead from the ground. At least, that is what a YouTuber called Brian Haidet – a materials science PhD – has demonstrated in a video on his excellent AlphaPhoenix YouTube channel. En-route, he built a set of scales about 2m long and ...

The rev counter prototype is up and running

The cnc lathe rev counter prototype now works – with a bit of help from friends who can actually programme. On a signal generator, the display is rock-solid and spot-on – the crystal on the Arduino Pro Micro clone is doing its job. Find other CNC-related Engineer in Wonderland blogs here Attached to the perforated 48 hole synchronisation wheel output ...

Arduino reciprocal RPM meter progress

The parts arrived for the RPM meter that uses an Arduino and reciprocal counting to get a three-times-a-second update rate with 1rpm resolution. Arduinos plus ready-made modules are a very qick route to custom test gear, although this time the TM1637 based display module introduced a couple of spanners: Find other CNC-related Engineer in Wonderland blogs here Firstly, the ebay ...

CNC lathe: Big thanks to kind open-source folk

The cnc lathe project needs a controller to replace the 40 year old custom controller within the lathe. It is a shame this has to be done, as it was capable of automated thread cutting, which appears to be the holy grail of home-build cnc lathes. Find more on the cnc lathe project here The in-built controller might even still ...

No-volt release with few new holes?

Some sort of sane no-volt release and emergency stop needs to be applied to the cnc lathe project (when time allows….) And before that time is available, so thought has to go into what arrangement is acceptable. Find more cnc lathe project blogs here It seems a shame to cut too many more new holes in the front, and certainly ...

More capacitor help please

Thanks for the help with the mystery tantalum capacitor on the Jay Electronics motor controller board – that is on its way to the bin as a consequence. Now that I am properly worried about capacitor failure, I have taken photos of two of the capacitors on the same board (plus the lovely new electrolytic replacement already installed – bottom ...

Excellent GaN psu introduction video

For those wanting a little more on the advantages of GaN power transistors in small mains power supplies, ElectrArc240 has created an excellent YouTube video. ElectrArc240 has clearly knows what he talking about and has spent a long time testing different aspects of two similar power supplies to succinctly demonstrate their differences: one with a GaN hemt main switch and ...

More detective work on the 1985 cnc lathe

A deeper dive into another board in the ancient cnc lathe revealed further quirks. The aim was to work out how the safety interlock worked – which uses the two relays on a board with digital logic and a big area with no components (photo). Find more cnc lathe project blogs here This took a while as there is a ...

Electronics Weekly

Electronics Weekly