“Customer requests initially sparked the development of the MLX90617,” said Melexis marketing manager Joris Roels. “However, the challenges of working with relatively small signals of infrared at short wavelengths made us question its feasibility.”

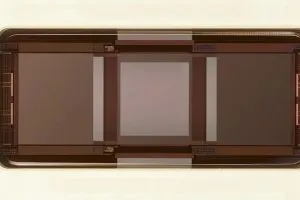

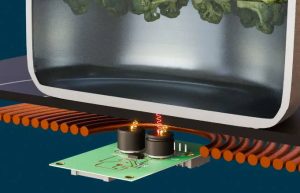

What was wanted was an alternative to measuring the back-side of the pan support surface, which is not at the same temperature as the pot base.

And the Melexis team manged it, producing an infra-red sensor specifically tuned to see though the type of ceramic glass used in induction hobs – which has now been commercialised as MLX90617.

And the Melexis team manged it, producing an infra-red sensor specifically tuned to see though the type of ceramic glass used in induction hobs – which has now been commercialised as MLX90617.

However, while it can detect radiation from the pot bottom, it can’t avoid also picking up radiation from the back of glass at the same time.

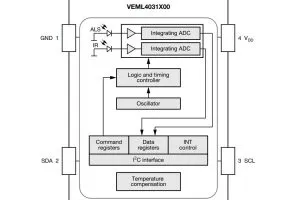

This is where one of the company’s earlier IR sensors comes in (MLX90614 or MLX90632) as it can only see radiation from the glass back, and not through the glass to the pot base, allowing the new sensor to be compensated.

This is where one of the company’s earlier IR sensors comes in (MLX90614 or MLX90632) as it can only see radiation from the glass back, and not through the glass to the pot base, allowing the new sensor to be compensated.

For best accuracy, compensation for the emissivity of the pot base can be applied, modelled from the reflectivity of the pot base measured by an LED and a light sensor.

“Through relatively simple real-time processing, it is possible to determine just the temperature of the cooking vessel’s base, ignoring the radiation from the ceramic surface and sensors,” said Melexis.

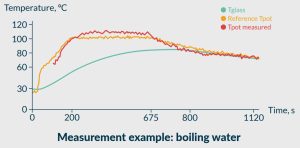

MLX90617 is factory-calibrated so that it can operate in ambients from 0 to +125°C, and is designed to measure cookware across +70 to +250°C.

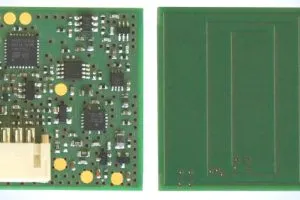

Inside, it has an IR sensitive thermopile chip, and a signal conditioning chip that includes low-noise amplifier, 17bit ADC and a DSP.

Packaging is TO39, it runs from 5V, and communicates through SMBus. A PWM output is provided for continuous reading in difficult EMC environments.

Electronics Weekly

Electronics Weekly